As the demand for hydrogen-powered systems grows, so too does the need for precise measurement technology in extreme environments. Hydrogen technologies often operate at cryogenic temperatures, where precision and reliability are critical for ensuring safe and efficient performance. Gantner Instruments is proud to offer state-of-the-art cryogenic measurement solutions, including our Q.bloxx A105 CR Module, designed specifically for applications in hydrogen production, storage, and fuel cells.

Cryogenic Precision with the Q.bloxx A105 CR

The Q.bloxx A105 CR Module is designed to provide highly accurate temperature measurements at cryogenic levels, ideal for use in hydrogen-powered engines and liquefied hydrogen storage systems. Featuring 4 galvanically isolated input channels, it supports popular cryogenic sensor types such as Cernox® and TVO, with selectable ranges up to 25 kΩ, which makes the module adaptable for use with a variety of cryogenic sensors, which is essential in the fast-growing hydrogen sector.

Key features of the A105 CR Module include:

- 7.5 µA sensor excitation: Minimizes sensor self-heating to reduce measurement errors, which is critical in maintaining accuracy at cryogenic temperatures.

- High-accuracy digitalization with a 24-bit ADC: Ensures stable, precise readings even in rapidly changing environments, with a sample rate of 10 Hz per channel.

- Sensor-specific linearization: Up to 32 calibration points allow for precise compensation of non-linearity in cryogenic temperature sensors, providing long-term stability and accuracy across various hydrogen applications.

Advanced Solutions for Hydrogen Storage Systems

Hydrogen storage and transport systems, especially those operating with liquefied hydrogen, are susceptible to extreme temperature variations. The Q.bloxx A105 CR Module ensures stable and accurate temperature readings, which are essential for optimizing storage conditions, preventing boil-off losses, and ensuring the structural integrity of hydrogen containment vessels. The module can handle high-resistance sensors and support extended measurement ranges, making it ideal for emerging applications where new sensor technologies are rapidly evolving.

For hydrogen vessel testing, the A105 CR supports continuous monitoring of the temperature within critical components, enabling real-time adjustments to maintain optimal operating conditions. The module’s precise measurements help prevent performance degradation due to thermal stress or uneven heat distribution in the system.

Maximizing Efficiency in Cryogenic Hydrogen Testing

Gantner Instruments’ cryogenic measurement solutions help push the boundaries of innovation in hydrogen technology. By ensuring long-term measurement stability and reducing sensor self-heating, our modules provide the reliability required for hydrogen storage, fuel cell development, and cryogenic engine performance. Whether integrated into R&D projects or full-scale industrial applications, the Q.bloxx A105 CR Module delivers the precision necessary to support the future of hydrogen energy.

The Q.bloxx A105 CR Module is just one of the advanced measurement modules that can be integrated into the Q.series X system for a complete characterization of thermal, mechanical, and electrical working conditions in extreme environments with extreme accuracy.

Proven Expertise in Cryogenic Hydrogen Applications

Gantner Instruments has a strong track record of providing advanced measurement solutions for complex cryogenic applications, including significant projects in nuclear fusion research and hydrogen energy systems. Our ability to deliver precise, reliable, and customizable data acquisition systems has led to our selection for several demanding projects.

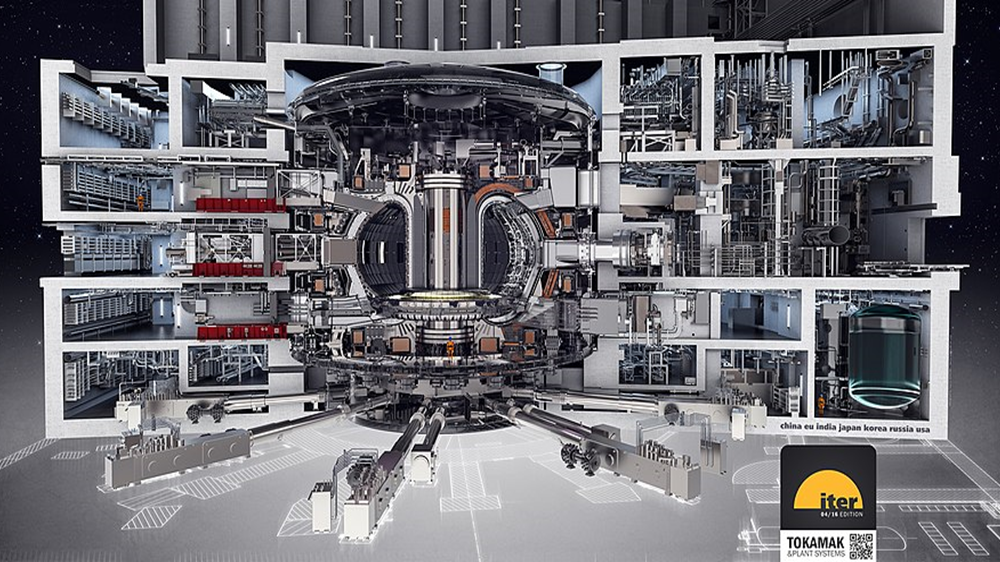

ITER Cryogenic System Monitoring

Reason for Selection: Our capability to deliver highly accurate temperature measurements at cryogenic levels, combined with custom solutions to mitigate magnetic field interference, made us the preferred choice for ITER’s critical monitoring needs. The Q.bloxx A105 CR module’s low excitation current minimized sensor self-heating, ensuring precise measurements essential for maintaining the superconducting magnets at temperatures as low as 2–3 K.

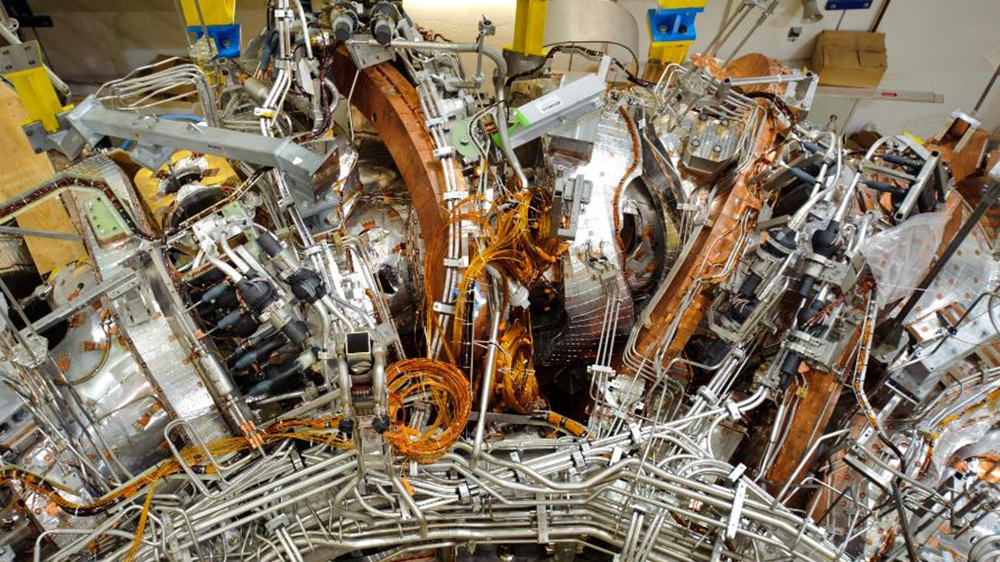

Wendelstein 7-X Fusion Reactor Monitoring by Max Planck Institute for Plasma Physics (IPP)

Reason for Selection: The project’s requirements included precise measurements across a wide temperature range, resistance to strong magnetic fields, and minimal sensor self-heating. Our intermittent measuring modes reduced power to the sensors, minimizing self-heating and thermal voltages, which was crucial for accurate measurements in the challenging environment of a fusion reactor.

More articles

Q.series interface with the Moog Aerospace Test Controller

The amount of data generated in an aircraft structural test program continues to grow. The density of load introduction points (actuators) and sensors (strain gauges, thermocouples, LVDTs) on a test article is increasing progressively and model validation requires higher data sample rates to capture more detail. The risks and costs involved in aircraft validation and certification are significant, and the requirement for quick entry-into-service is high. To minimize the impact of retrofitting in-service aircrafts, the ability to generate test results quickly is crucial to the success of a test program.

Read more...IPERMON – Innovative Performance Monitoring System for Improved Reliability and Optimized Levelized Cost of Electricity

Currently, a vast amount of research institutions and organizations are focusing on ways to improve the operation, reliability and consequently the output of PV systems. An important aspect yet to be targeted remains the procedural and standardized approach to calculate accurately the factors behind the various performance loss mechanisms, while also detecting and diagnosing potential failures at early stages or before occurrence. Identification of degradation and failure modes at preliminary stages is important as these mechanisms directly influence the performance, lifetime and reliability of PV technology.

Read more...GI.service Asset performance optimizer

With the significant investments being made in distributed renewable energies, the global energy market is changing from a central supply concept to a decentralized system. This transition is presenting companies in the energy market with various strategic and technical challenges to achieve efficient operations.

Read more...Instrumentation Live 2025, United Kingdom

GI Systems Ltd, representing Gantner Instruments, is excited to announce its participation in Instrumentation Live, scheduled for Wednesday, January 22nd, at the prestigious UK National Motorcycle Museum in Birmingham.

Read more...