When considering automated test benches, integrating software with complex technological processes – whether mechanical, electrical, biological, or chemical – is a significant challenge. Developing such software requires programming expertise and deep knowledge of these varied domains. Since it’s rare for one individual to possess all this expertise, collaboration among specialists becomes essential, and clear communication is key to success.

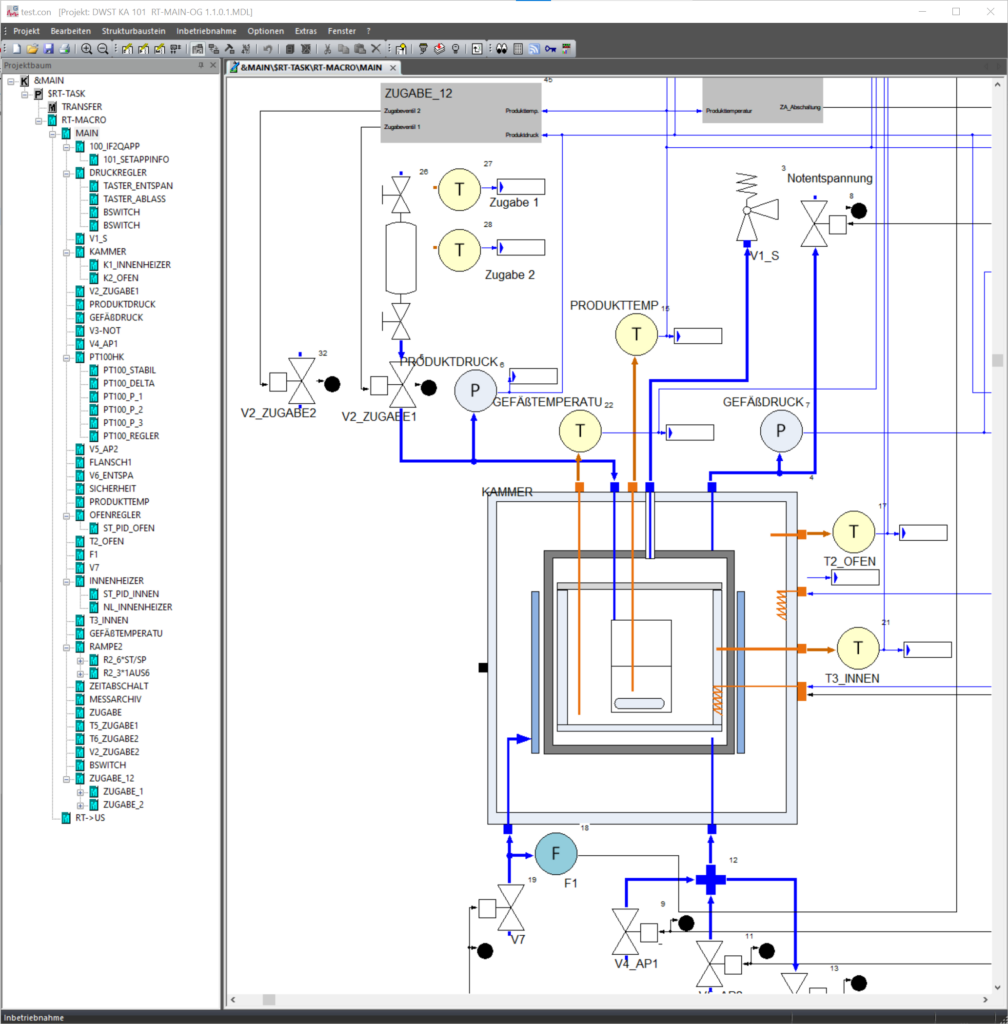

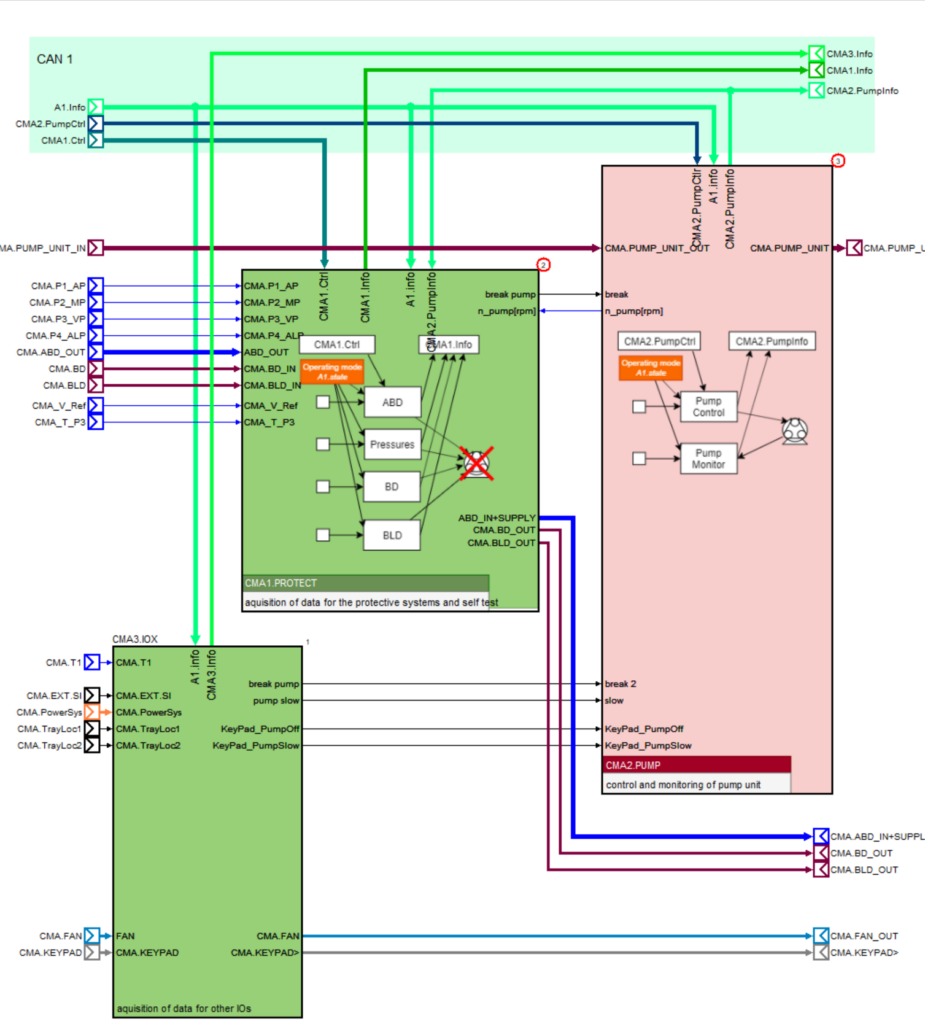

At Gantner Instruments, we’ve partnered with ProSign to address this challenge through test.con, a programming system designed specifically for measurement and control applications. test.con utilizes domain-specific symbols and function blocks, allowing engineers and technicians to model systems using concepts and language familiar to them. This approach facilitates interdisciplinary collaboration and enables domain experts to contribute directly to software development without needing to become programming specialists.

In this blog, we’ll explore how test.con streamlines the development of customized automation strategies and offers distinct advantages, especially when testing safety-critical systems.

The test.con Advantage

Domain-Specific Modeling:

test.con is tailored for the demands of measurement and control engineering. By using symbols and function blocks that represent actual components and processes, the software inherently communicates the structure and function of the application. This built-in clarity reduces the need for extensive documentation and helps team members quickly understand and contribute to the project. The models created are not just code; they are representations of the physical systems, making the development process more intuitive and efficient.

Integrating Expert Knowledge

By embedding domain expertise directly into the software model, test.con ensures that specialized knowledge is accurately reflected in the system. Engineers and technicians can work with elements that match their understanding of the system, reducing errors and streamlining the development process. This integration allows team members to focus on their areas of expertise while contributing to a cohesive whole.

Simplified Documentation for Quality Assurance:

The visual and domain-specific nature of test.con models makes documentation more straightforward. Since the models themselves convey significant information about the system’s structure and function, maintaining and updating documentation becomes less burdensome. This clarity is particularly valuable in safety-critical applications, where thorough documentation is essential for compliance and verification purposes.

Meeting Safety Standards in Test Bench Qualification

When dealing with safety-critical systems, test benches must meet strict functional safety requirements as specified in standards like IEC 61508 and ISO 26262. test.con’s modular architecture and standardized components make it easier to build test environments that are both comprehensive and suitable for formal qualification processes. By using test.con, organizations can create test benches that not only comply with these standards but also enhance the reliability and thoroughness of their testing procedures.

The Role of Simulation in Verification and Validation

Early Detection and Risk Mitigation

Simulation is a powerful tool for verifying and validating models before they are deployed in real-world environments. test.con supports the integration of simulation models, allowing developers to test and refine their systems thoroughly during the development phase. This proactive approach helps identify and correct issues early on, reducing the costs and risks associated with late-stage modifications. In sectors where safety is paramount, such thorough testing is not just beneficial but mandatory.

Detailed Analysis and Consistency

Working within a model-based environment like test.con enables detailed analysis of system behavior, with results that are consistent and reproducible. This is crucial for demonstrating compliance with safety requirements, as it allows for consistent verification of outcomes. Documenting these results strengthens the validation process and provides a solid foundation for any necessary certifications.

Seamless Integration into Test Automation

test.con integrates simulation directly into the test automation workflow, making it an integral part of the overall testing strategy. This seamless integration ensures that simulations contribute effectively to the validation and qualification processes, aligning with industry best practices for developing and testing safety-critical systems.

and analog signals from Gantner Instruments DAQ Modules

Adapting to Evolving Technologies

Technology and industry standards are constantly advancing, and test.con is designed to evolve accordingly. Continuous development efforts ensure that test.con incorporates new features and stays compliant with the latest regulations. This adaptability means that users can rely on test.con to meet emerging challenges and maintain best practices across various technological fields

Summary and Outlook

test.con offers a practical and efficient solution for developing automated test benches, particularly in safety-critical applications. By leveraging domain-specific modeling, integrating expert knowledge, and simplifying documentation, test.con enhances collaboration among specialists and streamlines the development process. Its capabilities support the creation of robust, compliant test environments that stand up to rigorous industry standards.

Discover How test.con Can Improve Your Test Automation

If you’re looking to enhance your test bench development while ensuring compliance with industry standards, test.con provides the tools you need. Explore how this specialized software can help you achieve efficient, reliable, and safe test automation.

Learn more about test.con and take the next step toward optimizing your test automation strategy.

More articles

Global Industrie Paris 2024

Join Gantner Instruments from March 25th to 28th, 2024, at Global Industrie in Paris, France.

Read more...High Performance Measuring Module D107 for Frequencies

The Q.bloxx D107 is a new measurement module for the acquisition of frequencies and incremental signals. Due to its fast signal conditioning capability with a clock speed of 288 MHz, the new module is suitable for extreme measurement of rotational speeds, which were not previously possible in this price range.

Read more...Automotive Testing Expo Novi 2025

Get ready to supercharge your automotive testing game with Gantner Instruments at the Automotive Testing Expo North America 2025 in Novi, Michigan! From October 21 - 23, visit Booth 8060 to explore innovations that can help you achieve shorter product development cycles, greater efficiency, and better durability.

Read more...How to transform the data avalanche into insight

In a world of increasingly complex products and faster release cycles, the ability to accumulate and efficiently analyze test data has never been more important.

Read more...