MOSAiC – Multidisciplinary drifting Observatory for the Study of Arctic Climate

In September 2019, the German research icebreaker Polarstern has set sail from Tromsø, Norway, to spend a year drifting through the Arctic Ocean – trapped in ice. Getting stuck in sea ice is normally the last thing that ships want to do. However, the German icebreaker will be trapped in the Arctic ice for a year. That will enable polar researchers to investigate the polar winter while the Polarstern makes an unknown voyage on the sea currents.

The goal of the MOSAiC expedition is to take the closest look ever at the Arctic as the epicenter of global warming and to gain fundamental insights that are key to better understand global climate change. More than 70 research institutions from 20 countries are involved in the expedition.

Following the footsteps of Fridtjof Nansen’s ground-breaking expedition with his wooden sailing ship Fram in 1893-1896, the MOSAiC expedition will bring a modern research icebreaker close to the North Pole for a full year including for the first time in polar winter.

On board of the Polarstern is a data acquisition system from Gantner Instruments for measuring loads on the vessel’s steel structure. The measurement data is intended to provide a better understanding of ice resistance requirements in order to optimize future icebreaker ships.

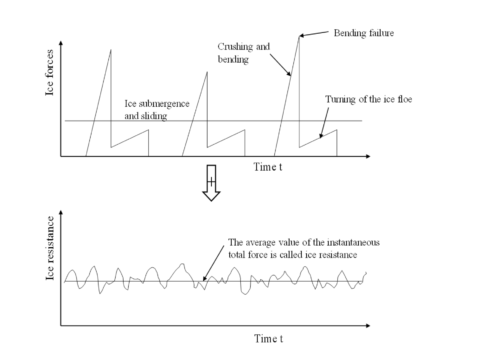

Understanding Ice-Induced Loads on Icebreakers

Even for the reliable Polarstern and her highly experienced crew, the MOSAiC expedition poses quite a challenge. The presence of sea ice is the main factor hindering such expeditions in the Arctic. Sea ice is a complex material and induces high pressures in contact with ships. Researchers from the Institute for Ship Structural Design and Analysis of Hamburg University of Technology (TUHH) participate in the MOSAiC program to get a better understanding of ice resistance requirements for optimizing the structural design of future ice breaking ships.

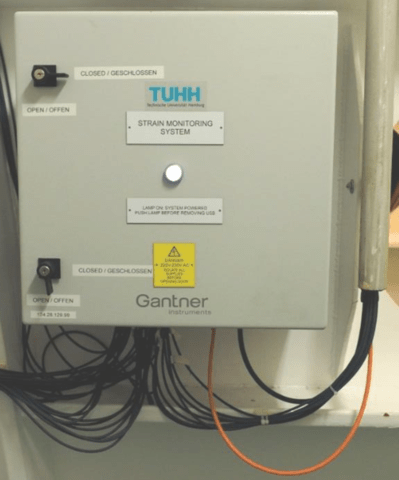

Strain Monitoring System

A Strain Monitoring System has been installed inside the Polarstern that uses a Gantner Instruments Q.series X data acquisition system for long-term measurement of loads acting on the vessel’s steel structure while frozen in ice. The data acquisition system acquires continuous data from 36 strain gage sensors installed on the icebreaker’s hull structure. Shear strain is measured with four active strain gages in a full-bridge configuration circuit, while linear strain is also measured using a full-bridge configuration but with two active and two passive strain gages for temperature compensation. The strain gage sensors are wired to a Q.bloxx XL A116 I/O module for accurate, low-drift signal conditioning. The Q.bloxx XL A116 features eight input channels for full, half and quarter bridge strain gages. Each channel is individually configurable and comes with pre-engineered signal conditioning functions like linearization, filtering, shunt calibration and lead-wire compensation.

In Situ Measurement Data is Valuable

The MOSAiC expedition provides a unique opportunity to gather valuable in situ data for a complete understanding of the ice induced loading on the vessel’s structure. Key to selecting the Q.series X is its ability to perform reliable long-term and stand-alone data logging without having a PC connected. As there is no active data link available from the Polarstern to shore, the data is saved on a USB flash drive and hand-carried to shore with each change of the crew. The USB flash drive is connected to a Q.station X high-performance edge controller that continuously writes data files to the flash drive. Each time the crew replaces a full USB drive, all intermediate measurement data is buffered and then transferred to the new USB drive. No data sample is lost. Redundant measurement data is written in parallel to a second USB drive.

With the Q.station X various data reduction techniques can be applied to reduce the measurement data yet produce the same analytical results. The Strain Monitoring System samples at a frequency of 1000 Hz, but data is written to the USB drives with a sampling rate of just 1 Hz to minimize the amount of disk space required. Besides capturing the actual measurement value, average, standard deviation and min/max values are calculated and stored to disk. When the monitoring system detects a sudden change in ice-induced load acting on the structure an event-based logger is triggered to record strain data around that event at a higher sample rate. This high-resolution data is then stored in a separate file for fast and efficient analysis.

An uninterrupted power supply (UPS), which is installed inside the cabinet, ensures data continuity during a temporarily loss of power. In the event of a persistent power outage the UPS sends a trigger to the Q.station X when its battery is running low. Data logging is then stopped and all write operations to the USB flash drives are terminated without any data corruption occurring. When the power returns the monitoring system starts up automatically and continues with measuring where it left off.

The Strain Monitoring System has been in operation for several months now. With the first crew exchange a first set of data will be successfully transferred to the TUHH in Hamburg. The Q.series X has proven itself again as a reliable data acquisition solution for long-term monitoring applications, even when trapped in ice.

Success factors

What is crucial to make these 12 month strain monitoring mission successful?

- Reliable and standalone data logging to multiple destination

- Smart data visualization of relevant events

- Easy and fast data transfer

- Design and production from one source with shortest delivery time

Would you like to know more about Gantner Instruments’ measurement solutions in vibration and wind? Find out how the unloading process of wood pellets from ship to silo tower was monitored, in harsh weather conditions in a remote area in Canada.

More articles

Fuel Cells: Advanced Measurement Techniques and Navigating the Hydrogen Market

The energy landscape is in a state of flux, shifting towards sustainable practices, and fuel cells have risen as a promising beacon of renewable energy. The mastery of fuel cells, their inner workings, and the nuances of their measurement, is central to this paradigm shift towards green energy. These devices, which are essentially electrochemical cells that transform chemical energy into electricity, promise a more sustainable, carbon-neutral future, provided we can harness their full potential. This blog post delves into the captivating scientific universe of fuel cell measurement, elaborating on the methodologies, complexities, challenges, and breakthroughs that make fuel cell technology so intriguing.

Read more...High Performance Measuring Module D107 for Frequencies

The Q.bloxx D107 is a new measurement module for the acquisition of frequencies and incremental signals. Due to its fast signal conditioning capability with a clock speed of 288 MHz, the new module is suitable for extreme measurement of rotational speeds, which were not previously possible in this price range.

Read more...Test Like You Fly, Fly Like You Test

When building a rocket there is a whole flight certification process, and qualification is an important part of that. It proves the hardware meets the requirements and performs the way it is designed to do. Of all parts of a rocket, the engine section is perhaps the most critical during launch. The weight of the massive rocket is pushing down, while the engines are pushing up with millions of pounds of thrust. Whether it is an engine for experimental rockets or for commercial spaceflight, adequate testing is critical to the success of each launch program.

Read more...IMAPS Herbstkonferenz 2024

Ensuring Quality and Reliability in Microelectronics: Insights from the IMAPS Herbstkonferenz 2024

Read more...