For the testing of these e-drives, we implemented the data acquisition solution and evaluation for a large German automotive supplier. Power consumption and speed are relevant to evaluating the efficiency of electromechanical systems. Since the motors are permanently installed into vehicle body parts, often only the electrical current and voltage signals are all that’s available for quality testing.

Using the Current Signal to Determine Motor Speed

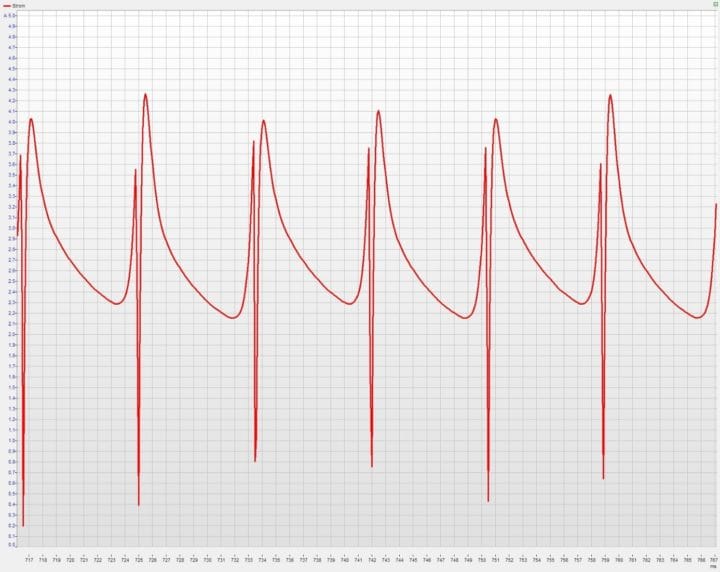

In a classic DC motor, the mechanical commutator leads to a brief drop in the current curve when poles are reversed. Depending on the design and number of poles of the motor, the quantity of current dips corresponds to one revolution. This model is also reflected in the current curve of brushless motors with electronic commutation.

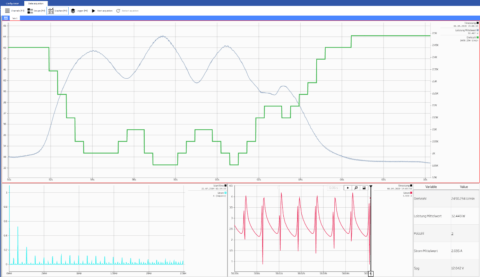

Figure 1 demonstrates the current curve of a motor over time. The current pictured here was measured with a Q.bloxx XL A107 I/O module and a shunt. The current drops visible in this example occur during commutation at intervals of 8.4 ms.

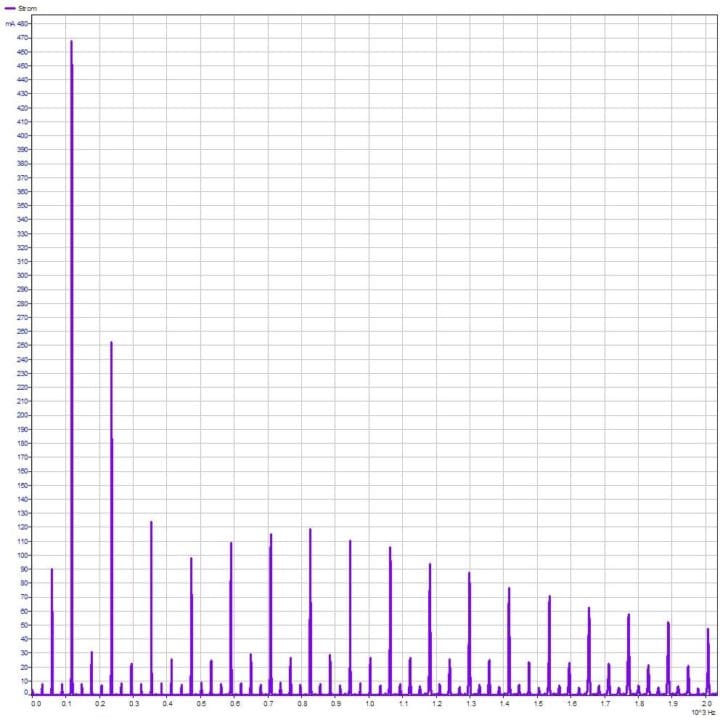

Accordingly, the spectrum of the current curve (Figure 2) shows its maximum occurs at 119 Hz. Assuming 3 commutations per revolution, this corresponds to a speed of 2380 revolutions per minute.

The spectrum can be performed both online and offline by Q.series X controllers. In this way, the engine speed can be determined continuously and live on the test bench using the current signal. The necessary configuration is performed in just a few steps.

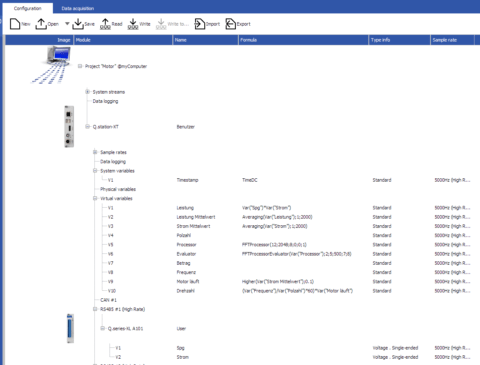

Quick-and-Easy Configuration on the Test Bench

The FFT function of the Q.series X controller offers, among other things, the possibility to evaluate the maximum of a spectrum within a selected frequency band by magnitude and frequency. The frequency of the maximum corresponds to the fundamental wave and is divided by the number of poles and multiplied by 60 to give the speed in revolutions per minute (rpm). Also, the current is used to detect whether the motor is in operation and whether the electrical power can be calculated.

This edge computing allows the motor speed to be determined without a separate computer.

Depending on the test bench configuration, data can now be transferred to the system control, e.g., via EtherCAT or visualized within GI.bench on the test bench PC or over the local network.

Simply Powerful Visualization

With GI.bench, you can create custom dashboards for visualization. Figure 4 shows the speed and power in the upper chart. When the motor is loaded, the speed decreases (green curve), while the power consumed increases (grey curve). Also, the current spectrum (blue), the current trace (red), and the parameters (table) are displayed numerically in this interface.

For references, demo programs and questions you can always contact us at info@gantner-instruments.com.

More articles

Wendelstein 7-X Stellarator

After 9 years in construction, the stellarator (nuclear-fusion machine) of the Max Planck Institute in Greifswald generated plasma for the first time on December 10, 2015. The reactor had been gradually ramped up over the past 12 months. The event was given extensive coverage in the media. Gantner Instruments specially developed sensors for temperature and strain measurement for the project, which are otherwise unavailable on the market.

Read more...China International Battery Fair 2024

Gantner Instruments at China International Battery Fair at the Chongqing International Expo Center, from April 27th to 29th, 2024.

Read more...Business Profitability and Edge computing

Our Gantner Instruments partner in the Philippines, DMS Engineering, organized a successful event on the 25th of November, 2022 at CEBU about using Edge Computing capabilities for Asset Monitoring to maximize business profitability.

Read more...Mercedes GLC 350e plug-in hybrid – Photo Session in Schruns

Daimler used our company building in Schruns as the backdrop for the photo shoot for this year’s world premiere of the Mercedes-Benz GLC 350e plug-in hybrid.

Read more...